Warranty: 3 Years

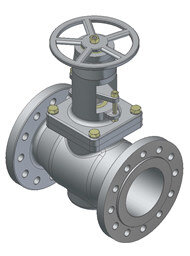

Type: titanium ball valve

Customized Support: Oem, Odm, Obm

Brand Name: QIYUEXIN

Application: General

Temperature Of Media: High Temperature, Low Temperature, Medium Temperature, Normal Temperature

Power: Hydraulic, Pneumatic, Manual, Solenoid, Electric

Media: Base

Port Size: Dn20-Npt

Material: Titanium

Product Name: Titanium ball valve

Pressure: Pn16

Packing: Wooden Case

Certificate: Iso9001

Working Pressure: Pn10 Pn16 Pn25

Working Temperature: -29~150℃,-40~450℃

Applicable Medium: Liquefied Petroleum Gas

Working Medium: Air Water Oil Gas

Suitable Medium: Corrosive Gas

Warranty Period: 3 Years

Types Of: Ball Valves

Certification: Gs

Support Customization: Oem

Place Of Origin: China

Medium Temperature: Normal Temperature, Low Temperature, High Temperature, Medium Temperature

Flow Medium: Acid, Gas, Water, Oil, Base

Place Of Origin: Shaanxi, China

Structure: Ball