Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Commonly used cast titanium alloys

1.1 Types

With the development of science and technology and production needs, different kinds of cast titanium alloys are developed and used in many fields. From the photographic composition, casting titanium alloy can be divided into α, β and α + β 3 types; from the strength, can be divided into medium-strength titanium alloy, high-strength titanium alloy; from the use of environmental temperature, can be divided into low-temperature titanium alloy (less than or equal to room temperature), medium-temperature titanium alloy (400 ℃), high-temperature titanium alloy (greater than or equal to 500 ℃) and anti-combustion titanium alloy, etc.. It can be seen that the use of cast titanium alloy is large, covering almost all aspects, and has a high market value.

1.2 Mechanical properties

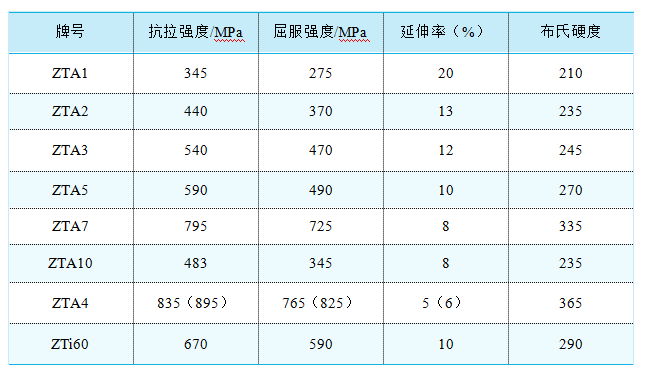

Cast titanium alloys are of various types such as ZTA1, ZTA2, ZTA5 and ZTC4, covering 3 types of α, β and α+β, which are expressed as TA, TC and TB respectively in China

Application of cast titanium alloy in valve industry

Take the most widely used ZTC4 cast titanium alloy as an example, its Al content is 5.5% to 6.75%, V content is 3.5% to 4.5%, the rest of the composition are Ti. from table 1 can be seen, ZTC4 cast titanium alloy tensile strength of 895 MPa, yield strength of 825 MPa. its mechanical properties and the performance of high-strength steel is relatively close to the use of steel can be a good alternative to steel, on the other hand, its density is only 4.4 g/cm3, much smaller than steel, which is conducive to equipment weight reduction. On the other hand, its density is only 4.4 g/cm3, much smaller than steel, which is conducive to weight reduction of equipment, and also retains the superior performance of titanium alloy corrosion resistance, which is not met by steel.

Therefore, in the future industrial production, if the need for weight reduction due to production needs, the choice of suitable casting titanium alloy for replacement, not only can effectively reduce the weight of the product, but also to ensure product performance, is a good choice.

Application of cast titanium alloy in valve industry

2.1 Marine titanium valves

Valve is usually composed of valve body, valve cover, valve flap, valve stem, hot piece, packing and drive parts, the body, valve cover selected materials for the main body materials, valve flap (gate), ball, valve seat, valve stem and seal seat and other selected materials called internal parts materials, in addition to fastener materials; valve common materials selected are gray cast iron, ductile iron, alloy steel and copper alloy, etc., can be selective diversification. But with the further needs of production, researchers found that in some harsh working environment and complex special conditions, conventional valve materials can not meet the production and research needs. At this time, titanium and casting titanium alloy because of the superior performance has attracted attention, titanium valves have been developed.

Marine pipeline system is located in a very harsh working environment, the performance of marine valves directly affect the safety of the pipeline system and even the overall performance. As early as the 1960s, Russia began the research of naval titanium alloy, and then developed marine β titanium alloy, which was used in the subsequent military naval piping system, which involved titanium alloy valves such as globe valves, check valves and ball valves, etc., using a wide range of types and huge quantities; at the same time, the civilian ship piping system also began to use titanium valves. Compared with the previously used copper alloy, steel, etc., the subsequent water test also shows that the use of cast titanium alloy, its own structural strength and corrosion resistance and many other aspects of high reliability, service life has also been significantly extended from the original 2 ~ 5 a can be extended to more than 2 times, has attracted widespread attention. The triple eccentric butterfly valve supplied by China Shipbuilding Research Institute in Luoyang, China for a certain type of ship is precisely to change the previous material selection and design scheme, using Ti80 as the main material, the service life of the valve is extended to more than 25 a, to improve the reliability and practicality of the application of valve products.

2.2 Aerospace titanium valves

In aerospace, cast titanium alloys also have a good performance, thanks to its good heat resistance and strength. This same period of the 1960s, the first trial of titanium castings in U.S. aviation. After a period of research, from 1972 casting titanium alloy began to be officially applied to aircraft (Boeing 757, 767 and 777, etc.), not only used more static structure titanium alloy castings, but also began to be used in key positions, such as key piping system valve control, commonly used valves are safety valves, check valves, etc., reducing the manufacturing cost of aircraft, increasing safety and reliability, while Because titanium alloy is less dense compared to other alloys, the weight is only about 60% of the same strength steel, so its widespread use can promote the aircraft to the direction of high strength and light weight steadily.

At present, aerospace valves are mainly used in pneumatic, hydraulic, fuel and lubrication and many other control systems, which are more suitable for corrosion resistance and high ambient temperature environment, and are one of the vital sector parts of aerospace vehicles and engines. Traditional valves often need to be replaced in stages, or even unable to meet demand, while with the aerospace valve market size is expanding rapidly, so the share of titanium valves due to its superior performance is also rising.

2.3 Chemical industry titanium valves

Chemical valves are generally used in high temperature, high pressure, corrosion resistance and differential pressure and other generally harsh environment, so the appropriate choice of materials for the valve chemical industry applications appear to be critical, the early selection of materials are mostly carbon steel, stainless steel, etc., the use of a period of time will occur rust and corrosion, the need for replacement maintenance. With the continuous development of casting titanium alloy technology and its superior performance is gradually discovered, titanium valves also appear in the eyes of people.

Take the chemical fiber industry purified terephthalic acid (PTA) production plant as an example, the working medium is mainly acetic acid and hydrobromic acid, which are very corrosive, nearly 8,000 units containing shut-off valves, ball valves and other valves need to be used, the variety is complicated and the quantity is huge, so titanium valves become a good choice, increasing the reliability and safety of use. In general, due to the corrosive nature of urea, the valves at the outlet and inlet of the urea synthesis tower can meet the service life of 1 a has reached the use requirements. And Shanxi Lvliang fertilizer plant, Shandong Tengzhou fertilizer plant and Henan Lingbao fertilizer plant and other enterprises have made several attempts to finally choose Titanium Valve high-pressure check valve H72WA-220ROO-50, H43WA-220ROO-50, 65, 80 and insulation stop valve BJ45WA-25R-100, 125 and so on for the import of urea synthesis tower, the service life is more than 2 a. It reflects better corrosion resistance [9] and reduces the frequency of valve replacement and usage cost.

The application of cast titanium alloy in the valve market is not limited to the above-mentioned industries, other aspects of development has good development, such as the development of Japan's new cast titanium alloy Ti-33.5Al-1Nb-0.5Cr-0.5Si, with low density, high creep strength and good wear resistance and many other advantages, it is used in the rear exhaust valve of automobile engines, which can improve the safety performance of the engine It has many advantages such as low density, high creep strength and good wear resistance.

The other applications of cast titanium alloys are more extensive than those of cast titanium alloys in the valve industry. Titanium and titanium alloys have good corrosion resistance, so for petrochemical and other industries with corrosive requirements is of great significance, in these industries, volume pumps, heat exchangers, compressors and reactors and other large equipment required for industrial production many are will use corrosion-resistant titanium castings, has the largest market demand. Medical field, because titanium is recognized as a safe, non-toxic, non-heavy metal precipitation safety metal, so many medical aids, human prostheses, etc. are cast titanium alloy as the material, especially in dental care, almost all tried and tested dental medical castings are made of industrial pure titanium and Ti-6Al-4V alloy, with good biocompatibility, mechanical properties and corrosion resistance. The properties are biocompatible, mechanical and corrosion resistant. On the other hand, due to the advantages of titanium and titanium alloy density, good performance, widely used in golf clubs, ball heads, tennis rackets, badminton rackets and fishing tackle and many other sports equipment, with its products made of light weight, quality assurance, very popular with the public. For example, the new titanium alloy SP-700 developed by Japan Pipe (N104) is used as the surface material for Taylor 300 series golf heads and is sold well in the global golf market.

Since the end of the 20th century, casting titanium alloy in petrochemical, aerospace, biomedical, automotive industry and sports and leisure fields has been from the initial trial to the current vigorous promotion and development, and gradually formed the industrialization and scale.

Limitations of the application

Conclusion

For titanium and its titanium alloy, on the one hand, it has superior performance and is an ideal substitute for many materials such as steel, and on the other hand, titanium resources are abundant, so it has received the attention of many researchers. Although there are still some problems in titanium resource mining, difficult smelting technology and processing difficulties, the valve industry and titanium industry are equally a vibrant and rapidly developing industry. Along with the future stable mining and production of Titanium Materials and the introduction and improvement of new processes, casting titanium alloys and castings in the valve industry will be more mature and tend to scale up the development of applications in other industries will also have broad application prospects.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.